Fixing a Faulty Air Compressor Filter Regulator

When your compressed air system starts acting up, the cause isn’t always the most obvious part. Sometimes, the problem lies in something as small as the air compressor filter regulator. This small but important device plays a big role in both airflow control and equipment protection. If it’s not working right, you’ll notice changes like poor tool performance, inconsistent pressure, or even moisture where it shouldn’t be.

Faults with the filter regulator can creep in quietly, especially if routine checks are neglected. Staying on top of these problems starts with knowing what the regulator does, how to recognize trouble signs, and how to set things right. Whether you’re running shop tools or handling plant maintenance, a clean and functional air compressor filter regulator keeps things flowing the way they should. It might not grab much attention, but it deserves it.

Understanding The Role Of An Air Compressor Filter Regulator

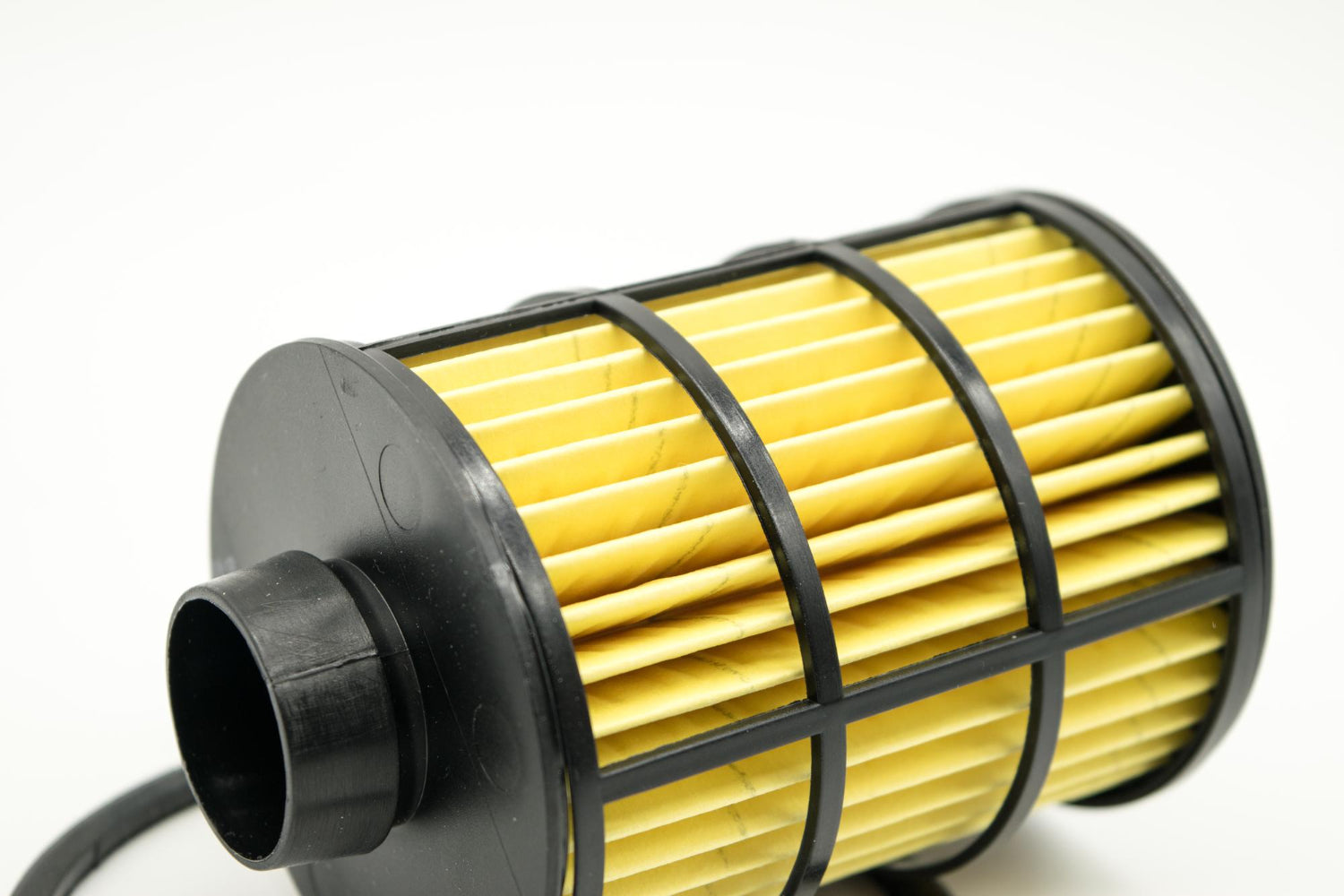

An air compressor filter regulator has two important tasks. It filters the incoming air to remove dust, oil droplets, and water particles, and it regulates the pressure that’s delivered to your tools or machines. These two simple functions make a big impact on how well your system runs and how long your gear lasts.

When compressed air runs through your system unfiltered and uncontrolled, you risk a host of problems. Contaminants like water and grime can clog tools and cause uneven wear. Even worse, too much pressure can stress your machines and cause them to wear out faster.

Many systems combine the filter and the regulator into one small unit, which helps save space and keeps things simpler. This unit blocks out dirt while making sure air pressure stays where you want it. But when the unit stops working right, the whole system feels it. Pressure gets unstable, tools slow down, and moisture may start showing up in your lines.

A good filter regulator makes maintenance easier with helpful features like a pressure gauge and a drain bowl. Regular inspections, wiping down the housing, and keeping an eye on pressure during daily use makes a big difference. Whether you're running a factory floor or a weekend project, this part keeps your tools working better, longer.

Common Issues With Air Compressor Filter Regulators

Most filter regulator problems reveal themselves clearly if you know how to spot them. Here are some of the most common issues people face and what usually causes them:

- Pressure drops: If pressure at the tool drops suddenly or often, the regulator may be blocked or worn out. Clogged filters are often the main culprit here.

- Leaks: Air escaping around fittings, valves, or seals could mean torn seals or loose parts. You can usually hear hissing or spot bubbles using soapy water around the fittings.

- Moisture buildup: When you notice water coming through your air lines or tools, your filter might be full, or the drain bowl might be stuck.

- Stuck adjustment knob: If you can’t turn or properly set the pressure, debris or rust may be jamming the control knob.

- Dirty filter element: A filter clogged with oil and dust will choke airflow and overload your system.

Imagine a shop tech noticing their power tools losing strength. At first glance, it may seem like the tool is failing. But checking the air compressor filter regulator reveals a blocked filter and a plugged drain. Replacing that filter and draining the water can return pressure to normal and keep tools performing like they should.

Most issues like these come from small maintenance tasks getting skipped. Catching them early can save you time and prevent much bigger repairs later. Whether that means cleaning a clogged filter or sealing up a fitting, small acts now avoid major problems later.

Step-By-Step Guide To Fixing A Faulty Air Compressor Filter Regulator

If your air compressor filter regulator is showing problems, a few not-too-tough steps can fix most situations. Here’s how to get things working right again:

1. Diagnose the issue:

- Look for signs of wear like cracked fittings, loose seals, or debris in the housing.

- Listen for short bursts or hissing that may come from leaks.

- Watch your pressure gauge. Spikes or slow recovery may point to internal flaws or a clogged filter.

2. Clean or replace the filter:

- Remove the filter carefully. If it’s reusable, blow debris out with compressed air. If it’s too far gone, swap it for a replacement.

- Make sure the new or cleaned filter sits right before securing the lid or casing back in place.

3. Adjust and calibrate the regulator:

- If the knob is hard to turn, add a light lubricant. Avoid forcing it.

- Turn the knob slowly and watch the gauge. Set the pressure based on the needs of your tools or system.

- Keep an eye out for drifting pressure after adjusting, which may point to an internal issue.

Following these steps helps to clear up the common causes of pressure loss or inconsistent tool performance. A working filter regulator gets airflow back to where it's supposed to be without second-guessing.

Preventative Maintenance Tips

Regular maintenance is what keeps your air compressor filter regulator doing its job. Here’s what to keep in mind and include in your routine care:

- Regular inspections: Check fittings and filters at least weekly. If something looks worn or feels off, don’t wait to fix it.

- Cleaning routine: Depending on how dusty or oily your worksite is, schedule a basic wipe-down and filter check routine that matches your usage.

- Replace when needed: Don’t delay swaps for filters, drain seals, or gauge covers. Replacing aging parts early reduces wear on your equipment downstream.

- Use quality parts: Cheap or mismatched filters can throw off performance. Stick to ones that match your system.

Doing just a bit of simple upkeep goes a long way. You won’t just be reducing costly breakdowns, you’ll get a smoother, more predictable system day after day.

Ensuring Reliable Performance

Getting the most out of your system is all about using the right items in the right spot. Here’s how you can make sure your air compressor filter regulator gives you consistent performance:

- Always match filters to the specs of your air compressor. Each system has pressure and flow limits that must be honored.

- Stick with brands or suppliers you trust so you're not constantly replacing parts.

- Don’t let an old filter or stubborn knob slow down production. Clean, adjust, or replace as needed.

Just a little time invested in smart choices gives your filter regulator the support it needs to keep doing its job. Small upgrades and consistent attention often lead to more stable pressure and happier tools.

Maintaining Efficiency and Reliability with Compressor Filter Hub

Carrying out ongoing maintenance isn’t just about fixing what’s broken. It’s about keeping everything running right from the start. A well-kept air compressor filter regulator doesn’t just protect tools, it helps save energy and improve work output.

When it comes time to replace filters or other components, it's always worth choosing options that are made to fit and perform as expected. Compressor Filter Hub offers aftermarket filters and components that support reliable, long-term operation. That means fewer delays, less downtime, and smoother performance whenever you need it.

To keep your air compressor system running at its best, make regular checks and maintenance a priority. The quality of your parts plays a big role in long-term performance. If you need dependable replacements, Compressor Filter Hub offers a wide selection to help. Browse options like our air compressor filter regulator for reliable operation and peace of mind with every use.