Industrial Applications for Filter Housings

Filter housings play a big part in keeping industrial systems clean and running the way they should. They help trap unwanted debris, particles, and moisture before those elements reach sensitive parts of a system. Without a proper filter housing, a filter won’t stay securely in place and might not perform as well, potentially leading to higher wear and more breakdowns in equipment.

Choosing the right filter housing isn't always simple. Materials, size, type, and flow requirements must all line up with the needs of the machine it supports. The wrong fit could slow things down or cost more in long-term repair and upkeep. That’s why it's important to understand what types exist and what kind of jobs they're best for.

Types of Filter Housings in Industrial Applications

Filter housings aren't one-size-fits-all. They come in several types, each suited for different tasks and conditions. Picking the wrong one can affect performance, but getting the right match helps reduce damage, manage pressure properly, and simplify maintenance.

Here are some of the most common types used in industrial settings:

1. Bag Filter Housings

- Bag filters are good for high-flow environments and work well when large volumes of particles need to be captured. The design allows for easy bag replacement, making maintenance faster.

- Pros: Holds large dirt loads, quicker filter changes, suitable for lower-pressure setups.

- Cons: Might not be the best for fine filtration; bags can tear if not installed securely.

2. Cartridge Filter Housings

- Cartridge housings offer more precise filtering. They’re used when tighter filtration is needed, like in food manufacturing or chemical processing.

- Pros: Better accuracy, handles small particles, works well under pressure.

- Cons: Slower change-outs compared to bags, replacement filters can cost more.

3. Duplex Filter Housings

- Designed for systems that run nonstop, this type allows one filter side to work while the other is cleaned or swapped.

- Pros: No need for shutdowns during maintenance, continuous filtration.

- Cons: Takes up more space, may require a higher upfront investment.

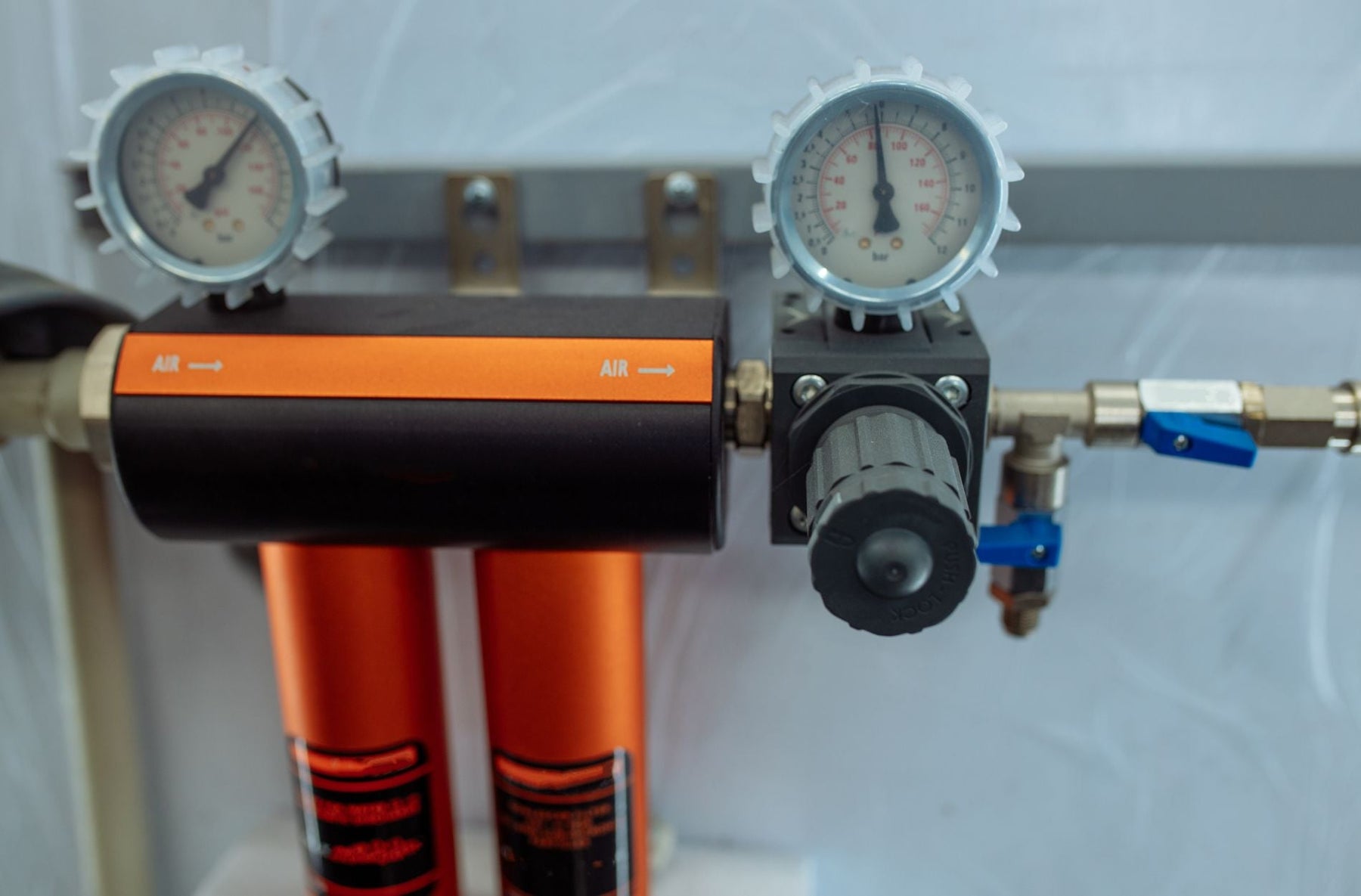

4. In-Line Filter Housings

- Common for point-of-use applications where compact, direct line filtering is needed.

- Pros: Easy installation, simple design, fits into tight systems.

- Cons: Best for light filtering tasks, not ideal for high-volume flow.

The right housing depends on what task it supports. A facility handling heavy equipment with large oil lines might go for a bag system, while a small pharmaceutical unit would likely choose a cartridge filter for its reliability and cleaner output. Matching the type of filter housing to the job it does keeps everything running better in the long run.

Key Considerations When Selecting Filter Housings

When choosing a filter housing, several factors play a role in making the right decision. Compatibility with the existing system is important, as is making sure the housing can manage the intended pressure levels and particle load. A filter housing that fits well will avoid creating flow issues or unnecessary wear on equipment.

Durability is another piece of the puzzle. Materials like stainless steel or high-grade plastics may be required depending on the operating environment. Systems that handle high temperatures or corrosive materials will benefit from more rugged construction. Picking the right material reduces the risk of cracks, leakage, or breakdowns under pressure.

Maintenance needs should not be overlooked. Some housings provide quicker access for filter replacements or internal cleaning. This can translate into cost savings by reducing downtime and extending the working life of the filters. Systems that require continual operation may need duplex styles that allow for changeouts without halting production.

Before making a final decision, it helps to assess the system requirements carefully. Taking flow rate, space limitations, contaminant types, and pressure levels into account ensures the filter housing fits the specific use case. If in doubt, consulting with someone who understands industrial systems can help narrow down the best options.

Common Industrial Uses of Filter Housings

Filter housings are used in lots of industries, each depending on their functions to protect key equipment. This includes removing particulates, oils, and moisture that could affect production quality or damage systems.

In manufacturing, bag filter housings play a big part in filtering out coarse debris from cutting, grinding, or milling processes. These are often used in systems that support machining or heavy tooling. Because they handle large volumes and allow for fast bag changes, they keep the workflow moving without frequent interruptions.

Chemical processing is another area where precise filtering is critical. Small particles, unwanted compounds, or process contaminants must be removed before they reach sensitive production stages. Cartridge filter housings are the go-to here, offering tight control and consistent results that support safety and product quality.

Food and beverage facilities also rely on filter housings. In beverage production, for instance, a clear and consistent product is key. Fine filters in sanitary grade housings help ensure this, while meeting cleanliness and safety requirements of the industry.

Petrochemical refineries may deal with thicker, more abrasive materials. Bag filters help remove heavier contaminants while remaining easy to replace. Their larger surface area and dirt-holding capacity make them well-suited for such tasks.

As a hypothetical example, think of a mid-size beverage company bottling flavored drinks. Their concern is product clarity and taste consistency. They use cartridge filters to strain out very fine particles and minimize the risk of flavor inconsistency. On the other hand, a processing plant handling steel and mechanical parts needs to trap abrasive debris from fluids used in cooling or cleaning. Bag filters are placed at different points in their process to protect pumps and other hardware from damage.

Each application shows how different filter housing types can play a key role based on what an operation needs.

Maximizing Performance With Regular Maintenance

Even the best filter housing won't do its job well without regular upkeep. Failing to maintain them can lead to clogs, system failures, or uneven fluid flow, all of which reduce efficiency and increase service costs.

Follow these steps to stay on top of maintenance:

- Schedule routine checks for damage or wear on seals and housing bodies.

- Replace filters and other components on a set timetable based on system usage.

- Clean interiors during each filter change or when performance drops.

- Keep spare filters and parts on hand to avoid downtime during unexpected issues.

- Chart performance readings for indicators like pressure drops, which may point to blockages or system troubles.

Using a maintenance schedule ensures filters stay effective and prevents problems before they start. Even something as simple as changing out a filter on time can prevent far costlier damage in pumps, motors, or lines fed by the housing.

Tools like duplex systems are helpful here. They offer continuous function during changeouts, great for operations that can't afford to pause activity. When combined with tracking tools and solid internal processes, maintenance becomes much easier to manage.

Keeping Your Industrial Systems Efficient

Choosing and caring for the right filter housing makes a real difference in how well your equipment runs. It protects your machinery, reduces strain, filters out harmful stuff, and lowers your total maintenance needs. That adds up to fewer problems, more uptime, and a smoother operation across the board.

Whether you work in manufacturing, food production, or chemical processing, matching your equipment with the right filter setup pays off. Every detail matters, from the material you're processing to the level of precision your operation needs. And once you have the right setup in place, taking the time to inspect, clean, and replace parts routinely keeps everything moving just the way it should.

To make the most of your industrial systems, it's important to choose the right equipment and maintain it well. Whether you're tackling large debris or fine particles, having the right filter housings in place makes a world of difference. At Compressor Filter Hub, we're here to support your operations with reliable, high-quality solutions designed to keep your machinery running smoothly.