Protecting Your Air Intake Filter Investment

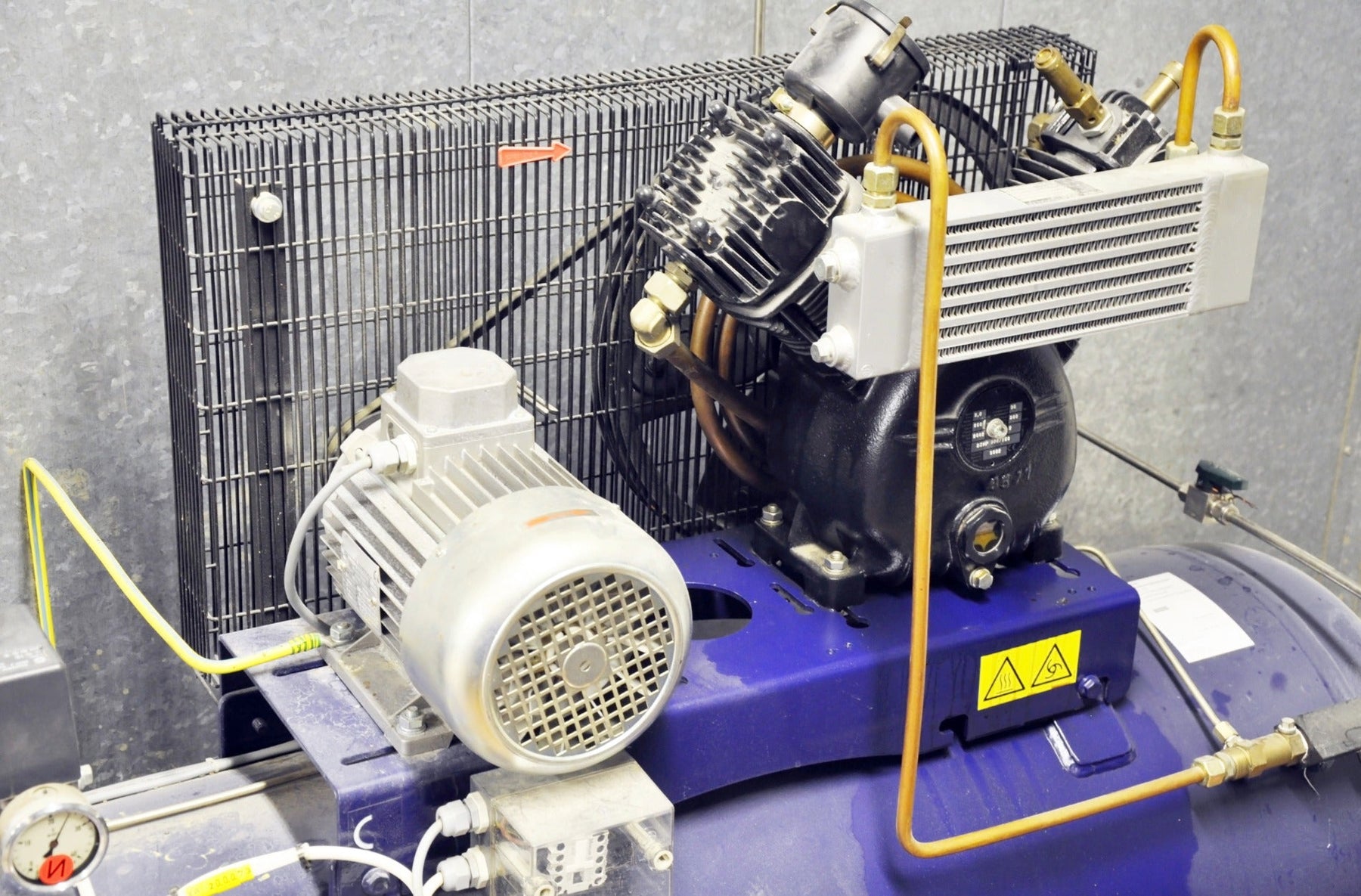

For many industrial systems, compressors serve as the core of daily operations. When a compressor goes down, it’s not just an inconvenience, it can shut down entire processes. That’s why keeping each part of the system in shape matters, especially when it comes to air intake filters. These filters do more than catch dust. They help keep the whole operation running smoothly by ensuring clean airflow into the compressor.

But here’s the thing, air intake filters don’t last forever. Without the right upkeep, you can end up with clogged filters, stressed equipment, and expensive downtime. This article breaks down how to protect the investment you've made in your filters. We'll walk through how they work, what puts them at risk, and what simple steps can keep them performing longer.

Why Air Intake Filters Are Important

Air intake filters act as the first line of defense for compressors. When air is pulled into the system, it's full of unseen stuff like dust, mold, pollen, dirt, and even oil vapors depending on the environment. The filter traps these particles before they reach the compressor’s internal components. Without that step, any of those contaminants could damage the system or cause it to work harder than it needs to.

When a compressor has to work extra hard because its filter is clogged or ineffective, it can lead to early wear and tear. Over time, that increases the chance of breakdowns and cuts down the system’s lifespan. The cleaner the air entering the compressor, the less work the rest of the system has to do. A properly working intake filter also promotes better energy efficiency, as the system isn’t fighting to pull in air through layers of grime.

It’s helpful to think of it like using a strainer in the kitchen. If you're boiling pasta and pieces of old food clog the strainer or it's damaged, it becomes much harder to drain water effectively. The same goes for air intake filters. Once they’re dirty, nothing flows properly and everything gets backed up. Keeping the filter clean makes the whole process work like it’s supposed to.

Common Risks to Your Air Intake Filters

Even the best air intake filters won’t last if they’re used in harsh or unpredictable environments without proper monitoring. Some risks are obvious, while others catch users off guard. Here are a few threats air intake filters face in most systems:

1. Dust and debris: Whether you're in a clean shop or a dusty warehouse, airborne particles are always present. They slowly clog the filter over time.

2. Moisture: High humidity or exposure to rain can get into the intake system. Wet filters are less effective and can grow mold.

3. Oil and vapors: In factories or garages where oil-based tools are common, vapors can stick to filters and attract even more dirt.

4. Extreme temperature swings: Going from hot to cold environments can damage filter materials or cause condensation, both of which lower filter performance.

5. Neglect: One of the biggest threats isn’t the environment, it’s forgetting to check or change the filter. A filter left unchanged for months is likely doing more harm than good.

Staying aware of these risks can make a big difference in how long your filters last. Whether you’re working in a woodshop, installing units onsite, or running a plant, knowing what can cause wear helps you plan ahead. It’s all about putting filters in the best position to do their job and spotting issues before they get expensive.

Best Practices for Protecting Your Investment

Keeping your air intake filters in shape doesn't have to be hard. A few regular habits can make all the difference in your compressor's performance and lifespan. First up is routine inspection. Set a schedule to check the condition of the filters, ensuring they aren’t clogged or damaged. Regular checks let you catch issues early before they cause bigger problems.

Next, make cleaning a priority. While some filters are disposable, others are designed to be cleaned and reused. Knowing which type you have, and following the correct method for cleaning, maximizes the life of your filters. Always make sure you handle them gently to prevent tears or other damage.

Storage is another factor that impacts filter life. Filters should be stored in a clean, dry environment away from direct sunlight or areas with excessive moisture. Exposure to the wrong conditions can degrade the materials, reducing their effectiveness before they even get a chance to work.

Here’s a quick checklist to simplify your routine:

1. Regularly inspect filters for dirt and damage.

2. Clean or replace filters as needed.

3. Store in a dry location, free from moisture and harsh conditions.

4. Keep a stock of spare filters for emergencies.

Choosing the Right Air Intake Filter for Your Needs

Picking the right air intake filter means knowing what you need for your specific environment and compressor model. Consider the ambient conditions where your compressor operates. Is it a dusty field, a humid workshop, or a clean indoor facility? Filters are designed with these conditions in mind, making sure you choose one that holds up in your environment.

Another point to consider is the compressor's size and specifications. Not all filters fit all machines. Double-check compatibility with your model to make sure you get a snug fit and proper function. It's also worthwhile to think about the types of particles common in your area, whether it be dust or oil vapors, and choose filters that effectively capture what's most prevalent.

Don’t forget to think about the benefits of different filter materials. Some materials might be better at trapping small particles or holding up against moisture. Choose the one that best matches your setup to get consistent performance.

Keeping Your Equipment Running Smoothly

Taking care of your air intake filters leads to smoother operations and fewer problems later. When filters are clean and well-maintained, compressors run more efficiently, helping reduce energy costs. But the benefits go beyond saving money. There's peace of mind in knowing your system is more likely to keep running without sudden breakdowns.

Make checking your air intake filters part of your routine. This small step helps them do their job, keeping your equipment protected and performing at its best. When you match the right filter with your compressor and take care of it, you’re building a solid defense against system failures.

Understanding what goes into choosing and maintaining air intake filters can go a long way in keeping your operations smooth and hassle-free. With the right filters and care, you keep your system running strong through every shift.

For ensuring that your compressor stays reliable and efficient, it's important to consistently care for its components. To find the best solutions customized for your setup, explore our range of high-quality air intake filters for compressors at Compressor Filter Hub. Equip your system with the ideal filters to safeguard and enhance your operations.