Replacing Your Air Coalescing Filter System

Air compressor systems work hard behind the scenes, keeping machines running and operations moving. For those systems to perform the way they should, proper maintenance is key. That includes knowing when and how to replace the filters that protect the compressed air. One of the most important of those filters is the air coalescing filter. It's responsible for catching fine mist, vapor, and other aerosols before they make it into your tools or equipment. When this filter gets clogged or worn down, it can affect more than just air quality—it can limit efficiency and damage system parts over time.

Changing out the air coalescing filter system at the right moment helps protect the entire setup. It also gives your compressor a better shot at lasting longer and performing better. Clean air flows better, uses less power, and reduces the chances of sludge or water collecting where it shouldn't. Whether you're running a small shop or managing larger equipment, knowing when and how to swap this filter is a big part of staying productive and keeping things running without avoidable breakdowns.

Understanding Air Coalescing Filters

An air coalescing filter plays a specific role in your air compressor system. It doesn’t just trap solid particles like dust or dirt. It’s made to catch very fine oil mist, water vapor, and other aerosol content in the compressed air. These things might sound harmless, but once they make their way into your machines, they can lead to sticky buildup, rust, or total failure of downstream components.

How it works is pretty simple. As the compressed air flows through the filter, the mist and vapor combine into larger droplets. This is called coalescing. Once the droplets get big enough, they fall into a drain bowl or are cleared away from the airflow, leaving cleaner air behind. Keeping that process working right takes a filter that’s still in good shape and not overloaded with contaminants.

Waiting too long to replace a coalescing filter comes with a price. It can restrict airflow, raise the compressor’s pressure, and force it to work harder than it needs to. That strain adds up, usually showing up in your energy bills or a decline in air output. In some cases, excess oil or water vapor can even make its way through, damaging sensitive tools or creating safety issues. A regular check on the filter system’s condition can save both money and hassle down the road.

Signs It’s Time To Replace Your Air Coalescing Filter

Like most parts in a working system, coalescing filters can’t last forever. Even if the filter seems fine from the outside, what's happening inside can tell a different story. Regular wear, buildup, and long run-times can lead to slower performance if the filter isn’t changed in time.

Here are a few common signs to look for:

- Reduced air pressure: A clogged filter cuts down on airflow. If your tools or machines aren’t getting the pressure they need, your filter may be blocked.

- Higher energy use: If the compressor motor runs longer to build pressure, it could be fighting against a dirty or saturated filter.

- Excess mist in output: If you're noticing visible vapor or oil where there shouldn’t be, your filter may already be failing.

- Unusual noises or heating: A struggling filter can cause the system to work harder, which may result in strange sounds or increased heat.

- Visible damage: Cracks, warps, or any damage to the filter housing are clear signs it’s time for a replacement.

Keep in mind that even without these symptoms, filters should be checked during routine maintenance. Some systems include service indicators that alert you when a pressure drop occurs across the filter. If your unit has that feature and it’s been triggered, it’s time to take action. Being proactive means less worry later and makes sure your compressor is always delivering clean, dry air where it counts.

Steps To Replace Your Air Coalescing Filter System

When it's time to replace your air coalescing filter, following a straightforward process ensures everything goes smoothly. Having a plan and knowing the right steps help make the replacement quick and stress-free.

1. Gather your tools: Before starting, make sure you have everything you need. This usually includes a wrench set, new filter, safety gloves, and any specific tools recommended by your compressor's manual. Having the right gear ensures the job gets done safely and efficiently.

2. Power down the compressor: Safety first. Make sure to turn off the compressor and disconnect it from its power source. Allow any built-up pressure to be released before you open up the system.

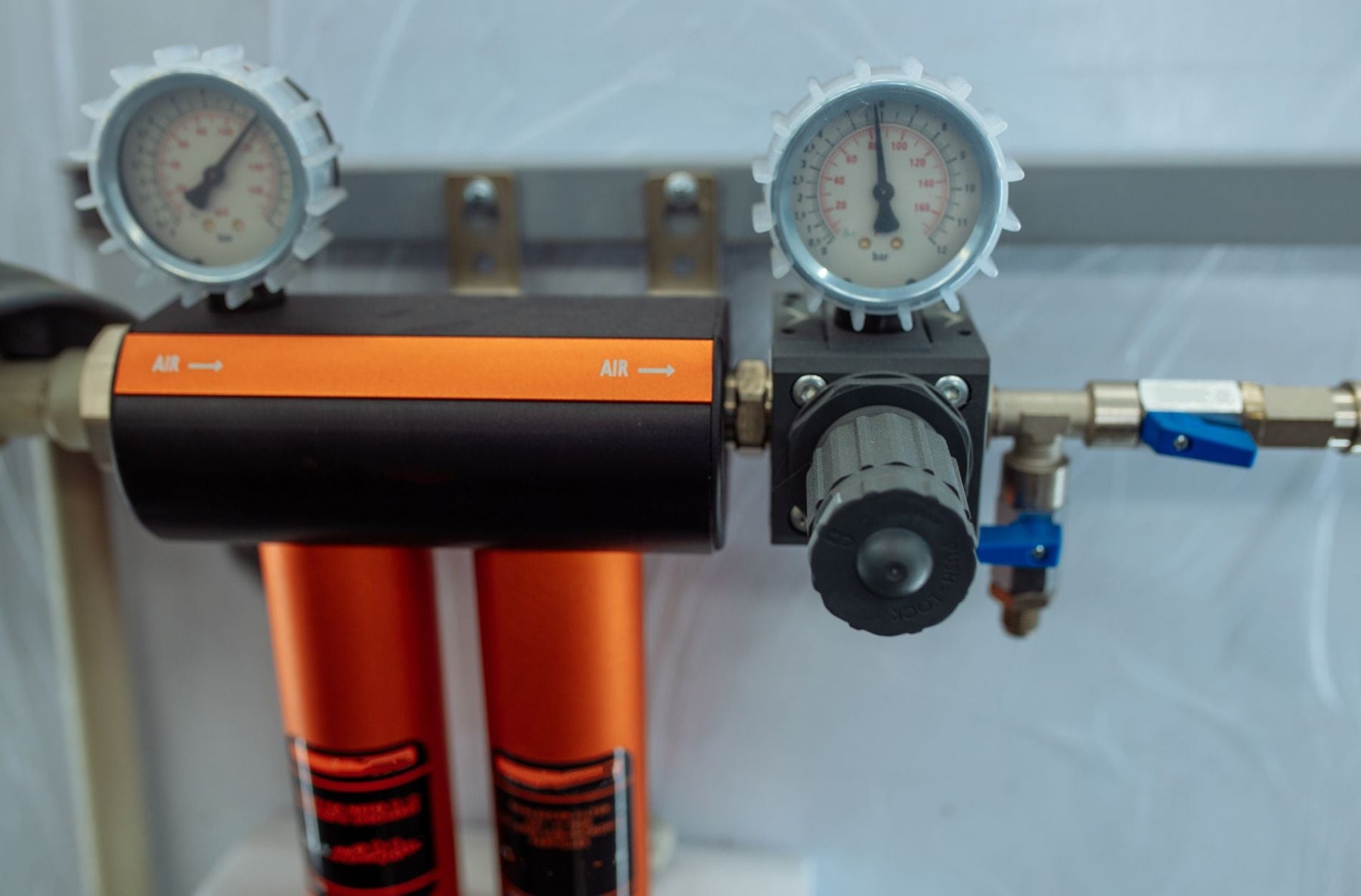

3. Locate the air coalescing filter: Find where your current air coalescing filter is installed. It's usually housed in a canister-like casing. Unscrew this casing carefully to remove the old filter.

4. Replace the filter: Take out the old filter and dispose of it correctly. Insert the new air coalescing filter, ensuring it fits snugly in its place. Align it according to your system's guidelines for optimal performance.

5. Reassemble and test: Once the new filter is in place, reassemble the system carefully. Double-check that everything is screwed tightly and properly sealed. Reconnect the power and gradually bring the system back online, checking for any leaks or unusual noises.

Always follow the manufacturer's recommendations while doing the replacement. This not only guarantees the proper fit but also avoids any invalidation of warranties. Regular checks after installation help confirm that everything runs smoothly. If unsure about any step, hiring a professional ensures the job is done right.

Benefits of Regular Filter Replacement

Replacing your air coalescing filter on a regular schedule carries rewards beyond just keeping things running. Consistent maintenance brings several advantages that improve both performance and longevity.

First, efficiency is enhanced when filters are clean. The compressor doesn't have to work as hard, which can lower energy consumption. This can mean savings on bills and fewer environmental impacts. Regularly swapped filters also lead to smoother airflow, reducing system strain and prolonging equipment life.

Besides efficiency, reliability gets a boost. With clean filters in place, the risk of unexpected malfunctions drops. This means fewer disruptions during your busy days and more trust in your equipment's reliability.

One example is obvious when we think of situations like a workshop where each tool's performance is important. Without consistent air quality, tools may not deliver the desired results, impacting the quality of the work. By ensuring regular filter replacement, not only does every tool work as expected, but it also contributes to overall workplace success.

Regular maintenance includes a little upfront time and attention but pays off with fewer headaches down the road. Maintaining a schedule for filter replacement secures long-term benefits and peace of mind that your systems are dependable when needed.

Keep Your Compressor Running Smoothly

Regularly maintaining your air compressor’s filters is a small step that brings significant benefits. From improved efficiency to fewer breakdowns, looking after your air coalescing filter is an investment in your system's future. Being consistent means your equipment stays reliable whenever the need arises.

Whether it's a busy shop floor or a quiet workspace, your compressor's performance supports day-to-day success. Taking these practical steps keeps everything running without a hitch. Your effort and attention ensure that your investments continue to pay off, increasing effectiveness and reliability.

Ready to optimize your compressor's performance? Explore our selection of high-quality air coalescing filter options from Compressor Filter Hub. Investing in the right filters helps keep your system running smoothly and efficiently, reducing potential downtime and maintenance headaches. Trust us to provide the reliable solutions your equipment deserves.