Maintaining Air Intake Filter Efficiency

Keeping your compressor running without hitches starts with something simple: clean air. When dirt, dust, or debris finds its way into a compressor's system, performance suffers. That’s where the air intake filter steps in. It acts as a frontline defense, catching airborne particles before they can cause damage. If this filter gets ignored, it slowly chokes the system and makes your operation work harder than it should.

Regular upkeep of the air intake filter for a compressor is one of the easiest things you can do to reduce wear and tear. It not only helps protect the compressor but also maintains airflow and system efficiency. Clean filters support consistent output, help keep energy costs stable, and can even extend the life of your equipment. That’s why it’s worth understanding how this small part makes a big difference.

Understanding Air Intake Filters

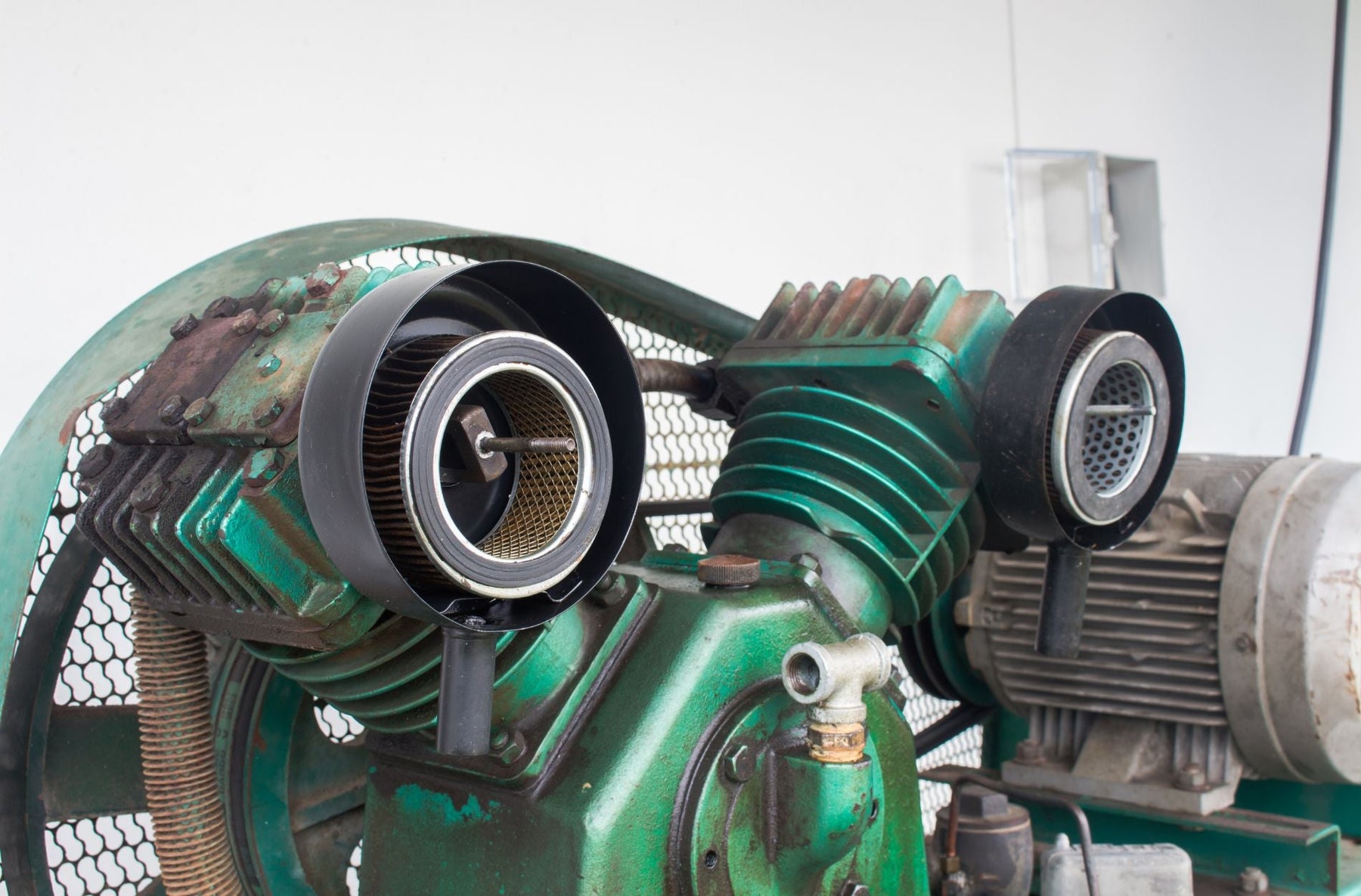

An air intake filter is designed to block unwanted particles from entering the compressor’s internal system. Without it, even small particles like dust or pollen could find their way into delicate components, leading to slowdowns or even breakdowns over time. The filter sits at the opening where the compressor draws in air, acting like a screen door for incoming airflow.

There are a few different kinds of air intake filters used in compressors, each built for specific environments and work conditions:

- Paper filters: Common in industrial settings, these filters are disposable and good at capturing fine particles. They’re easy to swap out, making them a solid choice for fast-paced work sites.

- Foam filters: Made from a spongy material that traps dirt, foam filters can be washed and reused several times. They’re great for areas with moderate dust exposure.

- Polyester or synthetic media filters: These are more durable and handle heavier dust loads. They’re often used in tougher work conditions.

- HEPA or high-efficiency filters: These are used where air cleanliness is top priority, like in food processing or electronics manufacturing.

Each type has its advantages, and choosing the right one depends on the work environment and how clean the air needs to be. If you're in a location with a lot of debris, like a woodworking shop or a construction site, you'll want a filter that can manage heavy dust levels. Lighter filters are usually fine in cleaner spaces.

Picking the right filter and replacing or cleaning it regularly doesn’t take much time, but it makes a difference in how well your compressor holds up.

Signs Your Air Intake Filter Needs Maintenance

It’s easy to tell when a filter needs attention if you know what to look for. Just like a car’s air filter, the one on your compressor gives off a few signals once it gets clogged or dirty. Ignoring these signs can slow your system and cause bigger headaches down the line.

Watch out for these red flags:

- Airflow loss: If your compressor seems weaker over time or isn’t delivering pressure like it used to, a clogged filter could be holding it back.

- Strange noises: A filter that’s working harder than it should can cause whistling or straining sounds in the system.

- Visible dirt and debris: If the filter looks dusty, coated in grime, or even damp, it’s probably due for a cleaning or replacement.

- Increased heat: A blocked filter causes added strain, often making the compressor run hotter than usual.

- Energy use climbs: Poor airflow can make the motor work harder, leading to longer cycle times and higher energy bills.

One example would be using a compressor in a workshop that sees a lot of sawdust. Over time, the dust collects and clogs the filter. The compressor then runs longer to reach full pressure, which increases power use and puts stress on the motor. Simply cleaning or replacing the filter early could have avoided all that.

Spotting these warning signs early helps stop more serious issues from developing. A regular inspection routine can help you stay ahead and keep things operating efficiently.

Steps to Maintain Your Air Intake Filter

To keep your air intake filter in good condition, set up a routine to inspect and clean it. Here’s a simple step-by-step guide:

1. Switch off the compressor: Always turn off and allow the compressor to cool before starting any maintenance.

2. Remove the filter: Locate the intake filter near the air intake system and carefully remove it.

3. Inspect the filter: Look for damage like tears, holes, or major clogs. If it seems too dirty or worn out, it’s time to replace it.

4. Clean the filter: If the filter looks reusable, use compressed air to blow out the dust and debris. Be sure to blow from the inside out to avoid trapping debris deeper in.

5. Reinstall or replace: After cleaning, put the filter back in place securely. If you’re replacing it, make sure the replacement is an OEM-equivalent part to match your unit’s performance standards.

OEM-equivalent filters are designed to fit just right and provide consistent filtration. Using quality replacements protects your compressor and extends the lifespan of your system.

Routine filter care keeps airflow strong and helps prevent avoidable breakdowns that can slow down your operation.

Benefits of Regular Maintenance

Taking the time to regularly clean or replace your air intake filter pays off across the board. It helps your compressor stay strong, saves on long-term costs, and keeps your operations running without delays. Here’s what you get out of sticking to a maintenance schedule:

- Improved efficiency: Clean filters let air pass freely, which means the compressor doesn't have to work overtime to maintain pressure.

- Reduced downtime: A well-maintained system is less likely to break down. Fewer interruptions mean more productivity.

- Longer compressor lifespan: Less strain on components leads to a longer working life for your equipment.

- Cost savings: Cleaner filters keep your energy bills steady and reduce the likelihood of costly repairs.

Even a quick filter check can head off much bigger issues. Regular upkeep doesn't take much but brings lasting results.

Keep Your Compressor Running Smoothly

Now that you've seen how air intake filter maintenance impacts compressor performance, it’s time to take action. Frequent checks and replacing filters when needed are simple steps that lead to smoother operations. Your equipment runs better, uses energy more effectively, and avoids unexpected breakdowns.

The air intake filter may not be the biggest part of your system, but it plays a big role in keeping things on track. When it works like it should, so does everything else. Make it part of your ongoing routine and protect your compressor from costly slowdowns.

Regular filter care might seem small, but over time it helps support consistent output, steady energy use, and dependable performance. Keeping the filter clean is one of the easiest ways to boost your compressor’s reliability and keep your operations running as expected.

Regular maintenance is the key to keeping your compressor working efficiently for years. If you're looking to improve performance and extend the lifespan of your equipment, consider updating your air intake filter for a compressor. Discover a variety of options at Compressor Filter Hub that can help enhance your system's reliability and save you time and money in the long run.