Setting Up Industrial Air Compressors

Setting up an industrial air compressor isn’t just about plugging it in and flipping a switch. It’s a key step that affects how well the entire system runs and how long it lasts. Whether you're installing a compressor for the first time or replacing an old one, having the right approach makes all the difference. A good setup supports better airflow, minimizes system pressure drops, and keeps energy use in check.

The good news is that most of what you need for a smooth setup comes down to making smart choices. From picking the right type of compressor to preparing your space the right way, every step builds the foundation for reliable performance. Let’s walk through how to get started with confidence and avoid common problems that can slow down your operation.

Choosing The Right Industrial Air Compressor

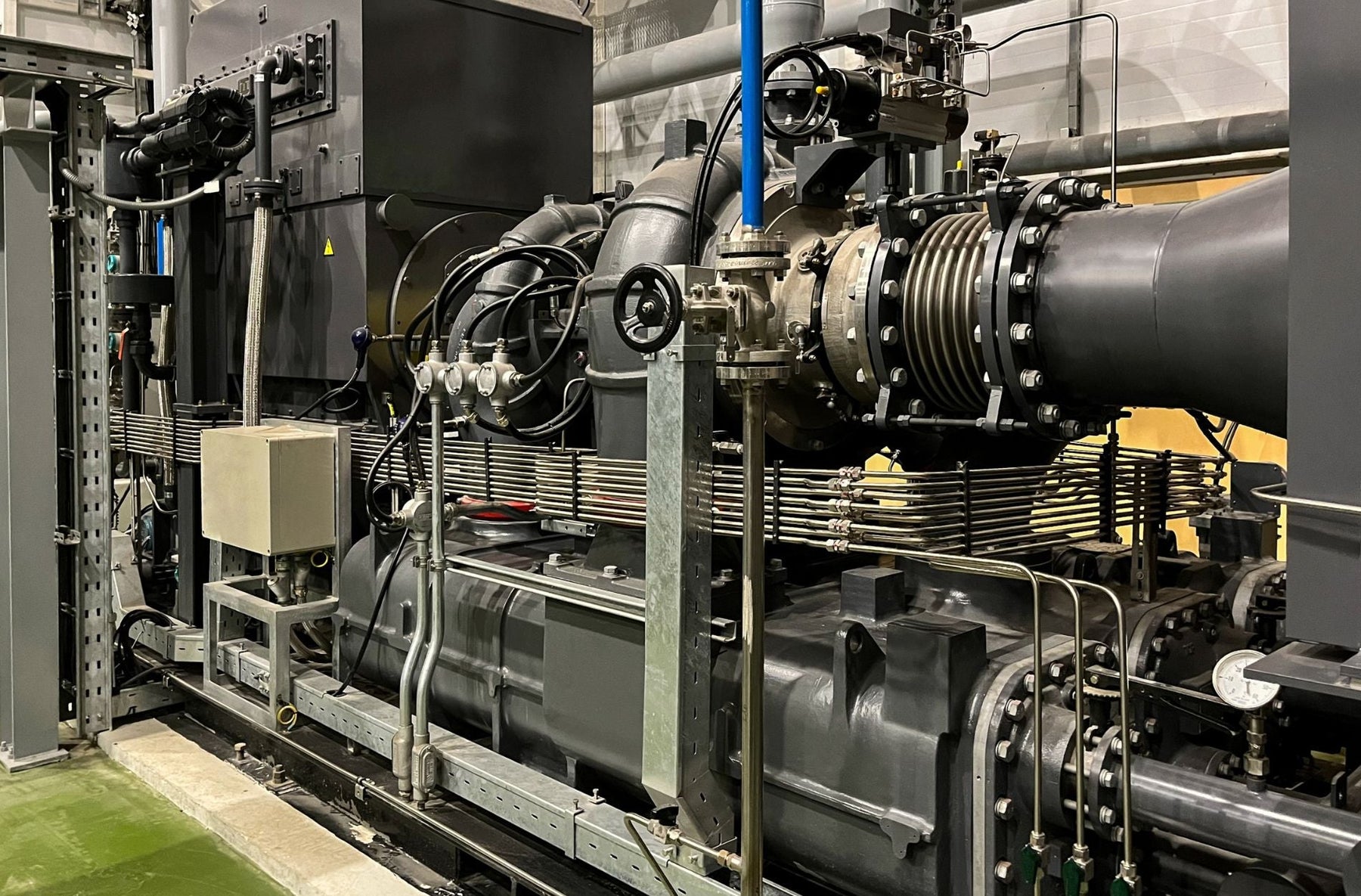

Not all compressors are built the same. Choosing one depends a lot on what you're using it for and where it's going. The size of your shop or facility, the tools that will run off it, and even the layout of your space all play a role. Compressors come in several types like rotary screw, reciprocating (piston), centrifugal, and scroll compressors. Each one does the job a little differently, so it's worth matching the type to your exact needs.

Here's a quick look at which kind suits what:

1. Rotary screw compressors work well in shops or plants that need steady, continuous airflow.

2. Reciprocating compressors are better for jobs that don’t need constant pressure but do need high bursts of power.

3. Centrifugal compressors are usually large-scale systems used in high-demand industrial settings.

4. Scroll compressors are quiet and compact, often used in places where noise control is important.

Once you’ve narrowed down the type, it’s smart to look at how much power it needs, the output it delivers, and how much room it will take up. These factors matter just as much as price or brand. When comparing options, try to work with an experienced industrial air compressor manufacturer that focuses on performance and support.

Also, consider your airflow demand over time. Some teams make the mistake of buying only for current needs and end up maxing out the system quickly. Planning ahead avoids that issue and gives you room to grow without needing a full upgrade too soon.

Site Preparation For Installation

After choosing your compressor, getting the installation site prepped is the next big step. Think of it like setting up a proper foundation. Without the right groundwork, even the best equipment can run into problems. Start with the basics: the space needs to be clean, flat, and strong enough to hold the weight of the compressor. If it's going on a raised platform or second floor, double-check the load-bearing specs.

Ventilation is another key factor. Compressors generate heat, and poor airflow can lead to overheating. Set yours up in a spot with enough clearance from walls or equipment. Fresh air should be able to move easily in and out of the area. It helps to avoid tight corners or enclosed spaces where hot air gets trapped.

Safety and access need to be part of the plan too:

- Leave enough space around the unit for technicians to access all sides during maintenance.

- Keep the pathway to the compressor clear to allow smooth transport of parts and tools when needed.

- Make sure the site has proper lighting and isn’t prone to dampness or debris overload.

Planning this way not only saves time during setup but also makes long-term maintenance much easier. Once all these pieces are in place, your space is ready for installation. The next step is getting the unit up and running the right way.

Installation Process

Getting the compressor installed correctly is crucial for smooth operation. Start by securing the unit on its designated base. Use anchor bolts to keep it from shifting during operation. Always ensure that the compressor is level as any tilt can cause mechanical stress. Align it properly to avoid any strain on piping or wiring connections.

Next, connect the compressor to the system. This involves attaching it to the main power supply and air distribution network. Double-check that all electrical connections are safe and compliant. Electrical cables should be secure and positioned to prevent accidental fraying or damage. If you're connecting multiple units, ensure each one is wired correctly to its designated power source.

When handling the air distribution lines, review your setup for tightness and leaks. All piping should be free of obstructions and routed in a way that minimizes bends. Bends can hinder airflow and strain the system. Also, use quality fittings to prevent leaks, which compromise performance.

Setting Up Accessories and Connections

Accessories like filters, dryers, and regulators complete the system setup. They're important to maintaining air quality and pressure stability, so connect these components carefully. Filters help remove impurities from the air, while dryers eliminate moisture, preventing rust and corrosion inside the system.

Here's how to connect the accessories:

1. Attach filters directly to the compressor's output line. Make sure they’re easy to access for regular cleaning and replacement.

2. Set up the dryer immediately after the filters. Ensure it's properly integrated so the air remains dry during operation.

3. Install a pressure regulator to handle variations in air pressure. Position it where adjustments can be made quickly if needed.

4. If your setup includes additional components like silencers or aftercoolers, place them in line with the other accessories for seamless integration.

Using OEM-equivalent parts guarantees that these components will perform reliably over time. They fit perfectly and function as intended, helping reduce risks of wear or failure later on.

Ongoing Maintenance for Optimal Performance

To keep your compressor in top shape, establish a regular maintenance routine. This covers everything from inspections to part replacements and keeps your system running strong.

- Conduct regular checks for oil levels and change oil according to the manufacturer's guidelines.

- Inspect and clean or replace air filters frequently to maintain peak airflow.

- Tighten any bolts and fasteners that may have loosened due to vibrations.

- Check hoses and seals for wear to prevent leaks and drops in performance.

- Schedule professional inspections periodically to catch potential issues early.

By staying ahead with maintenance, you can avoid surprise breakdowns and improve the lifespan of your equipment. Many common problems like clogged filters or worn gaskets are easy to handle when addressed early.

Ensuring Reliable Performance with the Right Support

A dependable support system is just as important as the compressor itself. Having access to top-tier aftermarket parts and expert guidance helps you keep things running without delay. That’s why partnering with knowledgeable suppliers makes so much sense.

A trusted supplier can connect you with the parts that meet your exact system needs. Whether it’s a set of air filters, a new regulator, or a full inspection kit, getting OEM-equivalent components means more peace of mind. You know they’ll fit right and last longer.

Help is never far when you’re paired with the right team. With continued guidance and fast access to the parts you need, your compressors will perform the way they’re supposed to. And when something does go wrong, you’ll be back up and running in no time.

When you're ready to ensure optimal performance and get the best out of your compressor system, it's worth exploring the options from a reliable industrial air compressor manufacturer. At Compressor Filter Hub, you can discover a range of high-quality parts that make your maintenance effortless and efficient. Check out our selections today to keep your operations running smoothly and minimize downtime.